HIGH-PERFORMANCE CT-M TYPE SOLID FUEL HEATING BOILER 800kW

CT-M type boilers for hot water production are designed and manufactured to utilize all types and forms of pulverized solid waste.

The heating boiler is designed and built to operate in accordance with the standards set by DECREE –02-1997 N.22, for energy recovery from raw and processed wood forming waste, including:

SAWDUST, MEDIUM-DENSITY FIBERBOARD, ENAMELED BOARDS, LAMINATED BOARDS, MASONITE, ABS AND PVC EDGES, WOOD CHIPS, ETC.

or for operation with liquid or gaseous fuels.

The boiler structure is entirely made of steel sheets, with a large water-cooled combustion chamber fully lined with high-quality refractory material, allowing complete combustion of materials with very low pollutant and unburned particle percentages.

Additionally, doors are provided for manual loading and regular maintenance.

The thermal generator consists of three horizontal flue bends with flue pipes immersed in water and tube bundles at the ends; the flue compartments have access doors.

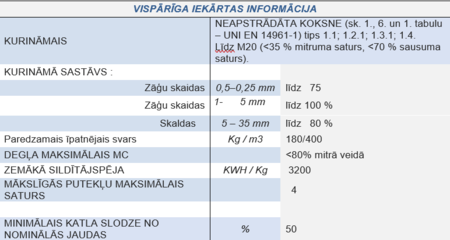

GENERAL BOILER FEATURES

This is a modern technology generator for hot water production with three efficient flue bends, and its dimensions comply with I.S.P.E.S.L.

The generator is a monoblock with flues and equipped with all necessary accessories for automatic operation according to current standards.

It contains a large volume of water and an appropriate thermal buffer.

The boiler’s total efficiency is very high, reaching 90% under optimal operating conditions.

H2O GENERATOR WITH FLUE TUBES, TYPE CT-M

Our hot water generators, type CT-M, are designed to recover the heat content of flue gases from the heat distribution system.

The large combustion chamber size allows gases to remain at high temperatures long enough to ensure complete combustion.

Counterflow water circulation with higher velocity in zones of intense thermal load allows for high heat exchange coefficients.

The architecture of the convective tube bundle with horizontally placed flue towers prevents ash deposits on heat exchanger surfaces.

Ash is collected in an expansion chamber located beneath the tube bundle, where Archimedean screws can be installed on request for automatic ash extraction.

Materials used in the construction are high-quality steel, and welding is performed manually by qualified personnel.

All construction phases are inspected by our internal control system. These features ensure high performance in terms of responsiveness and operation, guaranteeing continuous and long-lasting performance even under the most demanding conditions.

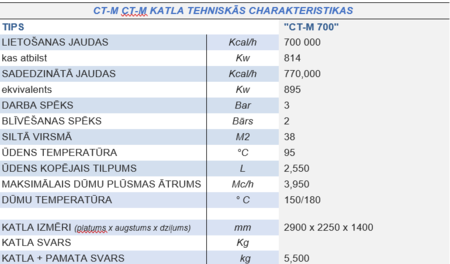

No. 1 HEATING BOILER MOD. CT-M 700 OUTPUT 700,000 Kcal/h (800 kW) FOR HOT WATER PRODUCTION, EQUIPPED WITH:

REGULATING THERMOSTAT

MANUAL THERMOSTAT

PRESSURE GAUGE

THERMOMETERS

FLUE GAS PROBE PT100

WATER PROBE PT100

LIQUID DEPRESSION GAUGE

DRAINAGE SYSTEM

SERIES OF BACKPRESSURE FLANGES

SOLID FUEL BURNER

No. 1 STATIC COMBUSTION CHAMBER WITH HORIZONTAL AXIS

Combustion occurs with a rotating flame.

1 central body facilitating product mixing with combustion air, made of electrowelded steel sheet, water-immersed, coated with monolithic refractory concrete spray with high aluminum content

WATER CIRCULATION SYSTEM

AIR COOLING SYSTEM

MULTI-SECTOR PRIMARY FUEL FEED SYSTEM

MULTI-SECTOR SECONDARY FUEL FEED SYSTEM

MOTORIZED CONTROL VALVES

SELF-EXTINGUISHING SYSTEM

AUTOMATIC BURNER TYPE AUTOFOCUS

with mechanical screw conveyor.

ELECTRIC MOTOR 4-POLE 380V 50HZ

GEARBOX with gears and inverter

BURNER CHAMBER base

FAN for combustion air with adjustment grids

FAN for secondary air with adjustment grids

PIPE with flanges to the tank

BURNER BASE made of cast iron with ventilation system

FIRE DETECTION PROBE

MINISILO

AUTOMATIC MINISILO

with a capacity of approximately 1 m³ for chips and sawdust to feed fuel material to the boiler.

Circular shape ø 1000 with level indicators, inspection door with safety microswitch, automatic filling levels, internal anti-blocking spring controlled by gear motor.

SAFETY VALVE

No. 2 TOTAL DISCHARGE SAFETY VALVES I.S.P.E.S.L. calibrated at 3 bar

No. 1 IMMERSION HEAT EXCHANGER in the boiler to dissipate excess heat, with automatically activated solenoid valve (according to I.S.P.E.S.L.01 / 04).

BOILER AUTOMATIC CONTROL PANEL FROM SILO TO FLUE GAS EXTRACTION

ELECTRIC PANEL

Electric panel for continuous combustion control and display of all parameters.

Continuous air and fuel regulation with variator and automatic shutters.

FLUE GAS EXTRACTOR AND DEPOSITION INSTALLATION

No. 1 ELECTRIC FAN high-efficiency reinforced centrifugal flue gas extractor with single suction inlet for high-temperature flue gases, with flat blade wheel, self-cleaning, motor mounted on slides with belt tensioners, in protective casing.

No. 1 SET OF CONNECTING CHANNELS

Made of stainless steel sheet for flue gas connection between BOILER - MULTICYCLONE - FLUE GAS EXTRACTOR - CHIMNEY.

No. 1 MULTICYCLONE inversion flue dust collector, inertial speed, to capture residual air particles from the combustion process at low speed. Vertically installed, with self-supporting structures made of extra-thick steel sheet, appropriately sized, equipped with doors for regular maintenance and servicing, bases, and ash collection tank.

No. 1 CHIMNEY made of hot-dip galvanized steel sheet pipe sections, with flanged connections using galvanized bolts, plate with hatch, supports, connecting rods, clamps, and cables, height 13.5 m x ø 800.